Radiotherapy Accessories

|

HEK cutting systems are microprocessor-controlled systems, operated by Windows-based software. A variety of software features are available such as direct plot on tray, TPS block and compensator input, DICOM-RT import, edit tool for contours, different possibilities for the cut path, cut simulation, label print etc..

|

|

Autimo 2D

The Autimo 2D system is an extremely reliable hot-wire cutter. Its four PLC-controlled, high precision industrial axes guaranteeing an excellent repeat accuracy. The system can be used with different cutting wires down to a diameter of 0.1mm. The windows based software runs on Windows 9x, ME, NT, 2000 and XP. The data import supports all common treatment planning

systems as well as DICOM-RT.

Important System Features

-

The use of high performance, maintenance free components guarantees excellent product reliability. Customer orientated, Windows based software with lots of useful tools for block production.

-

Multitasking allows simultaneous control of periphery equipment as well as the control of a second cutter.

-

Import filters for TPS export files and DICOM RT are available.

-

Easy-Mount wire holder for using pre-configured cutting wires in different diameters.

-

Internet update service via service contract

|

|

Autimo 2D Specifications

| Positioning Accuracy: |

0.004 mm |

| Dimension of Foam Block: |

min.: 100 x 100 x 20 mm

max.: 460 x 550 x 140 mm |

| Max. Cutting Area: |

350 x 490 mm |

| Cutting Speed: |

8 mm / s |

| Cutting Accuracy: |

< 0.5 mm |

| |

|

| Weight: |

59 kg |

| Supply Voltage: |

115, 230 V / 50, 60 Hz |

| Power Consumption: |

400 VA |

| Fuse Rating: |

10 A |

| Communication Port: |

RS 232 |

| |

|

| Dimensions: |

560 x 660 x 1000 mm |

Additional Autimo 2D Product Specifications

- Four Axes Hot-Wire Cutting System

- Three-Phase Stepping Motor Technology

- Cutting Wires with a Diameter of 0.1 mm or 0.38 mm

- Windows Software

|

Autimo 2.5D

The Autimo 2.5D is designed to mill compensators and beam intensity modulators in radiation therapy. Transfer options for common treatment planning systems are available as well as DICOM RT. User configured adjusting holes or the use of a compensator tray-mount system takes care of exact compensator positioning.

Important System Features

- The use of high performance, maintenance free components guarantees excellent product reliability.

- Customer orientated software with lots of useful tools for compensator milling.

- Generation of positive compensators enabling them to be milled out of full material (e.g. low melting point alloys).

- Import filters for TPS export files as well as DICOM-RT (option).

- Usage of milling cutters from 1 to 6 mm diameter.

- Compensator Tray-Mount System available (option).

- Windows Software (Windows 9x, NT4.0, ME, 2000, XP).

|

|

Autimo 2.5D Specifications

| Positioning Accuracy: |

0.005 mm |

| Repeat Accuracy: |

+/- 0.05 mm |

| Dimension of Foam Block: |

min.: 200 x 200 x 20 mm

max: 400 x 400 x 100 mm |

| Working Area: |

max: 300 x 300 mm |

| Milling Speed: |

max: 8 mm / s |

| |

|

| Weight: |

80 kg |

| Supply Voltage: |

230 V / 50 Hz |

| Fuse Rating: |

16 A |

| Communication Port: |

RS 232 |

| |

|

| Dimensions: |

720 x 850 x 770 mm |

Additional Autimo 2.5D Product Specifications

- Three-Axes Milling System

- Software Controlled from the PC

- Windows Software

|

Autimo 3D

The Autimo 3D is designed to mill compensators, beam intensity modulators and shielding blocks in radiation therapy. The computer-controlled, automated, 5-axes milling system cuts with or without divergence. Compensator and block data transfer from common treatment planning systems are supported as well as DICOM-RT. Customer configured adjustment holes or the special

tray-mount system guarantees exact compensator positioning and alignment. The Autimo 3D system is able to be used with styrofoam, low melting alloy and polyethylene material.

Important System Features

- The use of high performance, maintenance free components guarantees an excellent product reliability.

- Customer orientated Windows based software with lots of useful tools for compensator milling.

- Generation of positive compensators for milling out of full material (e.g. low melting point alloys).

- Import filters for TPS export files as well as DICOM-RT (option).

- Compensator Tray-Mount System available (option).

- Usage of milling cutters from 3 to 6 mm diameter.

- IMRT Module (option).

|

|

Autimo 3D Specifications

| Positioning Accuracy: |

0.005 mm |

| Dimension of Foam Blocks |

min: 200 x 200 x 20 mm

max: 600 x 450 x 100 mm |

| Max. Milling Area: |

400 x 500 mm |

| Max. Milling Depth: |

80 mm |

| Milling Accuracy: |

< 0.5 mm |

| Min Source Tray Distance: |

350 mm |

| |

|

| Weight: |

230 kg |

| Supply Voltage: |

230 V / 50 Hz |

| Power Consumption: |

1000 VA |

| Fuse Rating: |

16 A |

| Communication Port: |

RS 232 |

Additional Autimo 3D Product Specifications

- Five Axes Milling System

- Three Phases Cutting Motors

- Fully Automated Cutting of up to six IMRT Filters Over Night

| AUTIMO Accessories Alloys and Alloy Melters click to go to detail

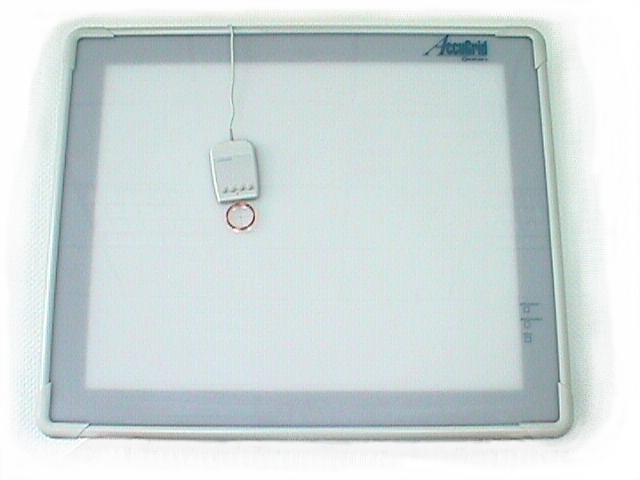

Digitiser

For entering contour data into the Autimo 2D :

|

|

|

Working Table

Plexi-Plotter

Special pen-plotter for direct block contour drawing on trays - for easy and precise mounting of alloy blocks :

-

Dimensions ( W x D x H ) : 300 x 650 x 400 mm

-

Plot area : A3

-

Repeat Accuracy : 0.1 mm

-

Connections : serial RS 232 and Centronics

-

Plotting on Plexi trays, foil and paper ( with additional adapter plate )

-

Weight : approx. 5.7 kg

|

|

|

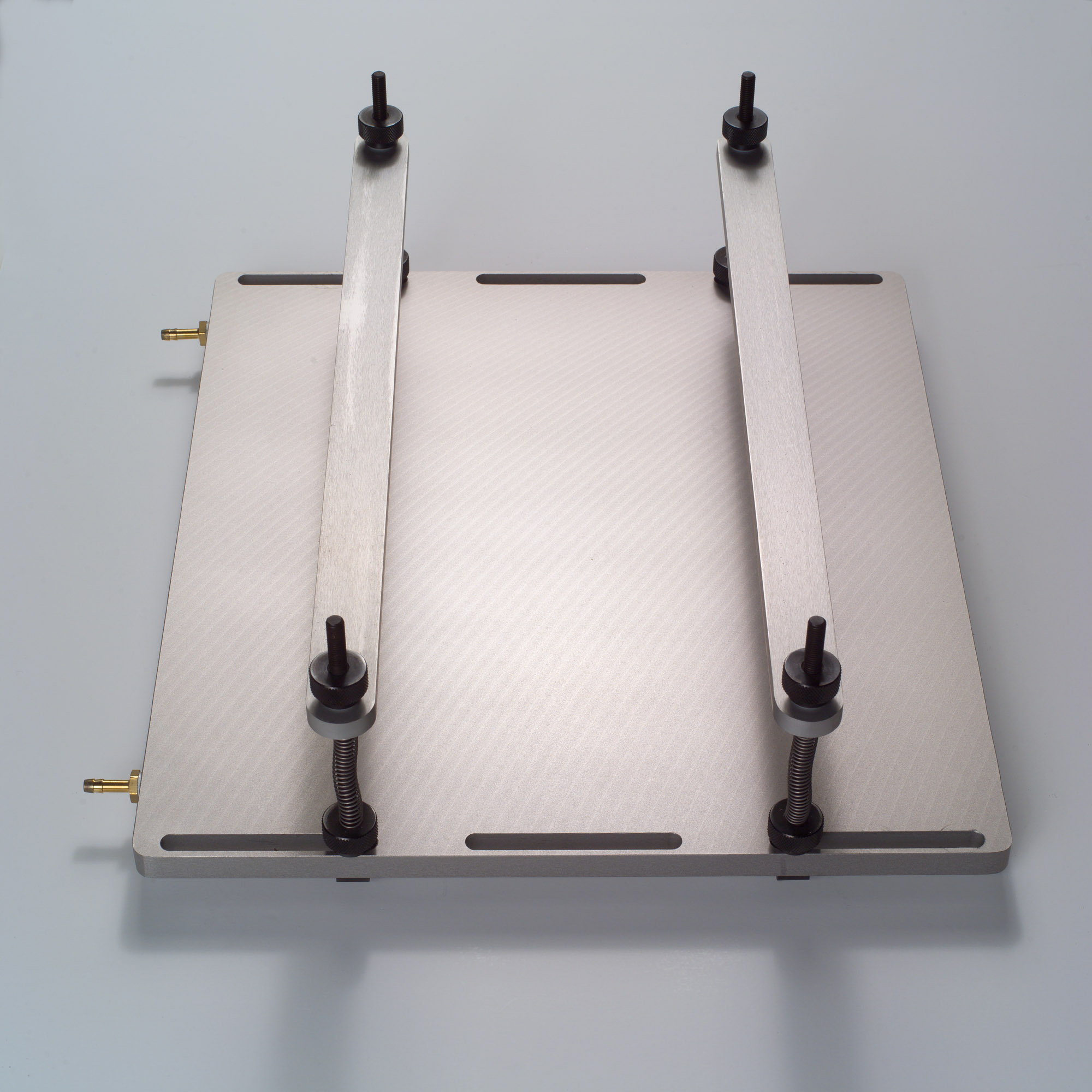

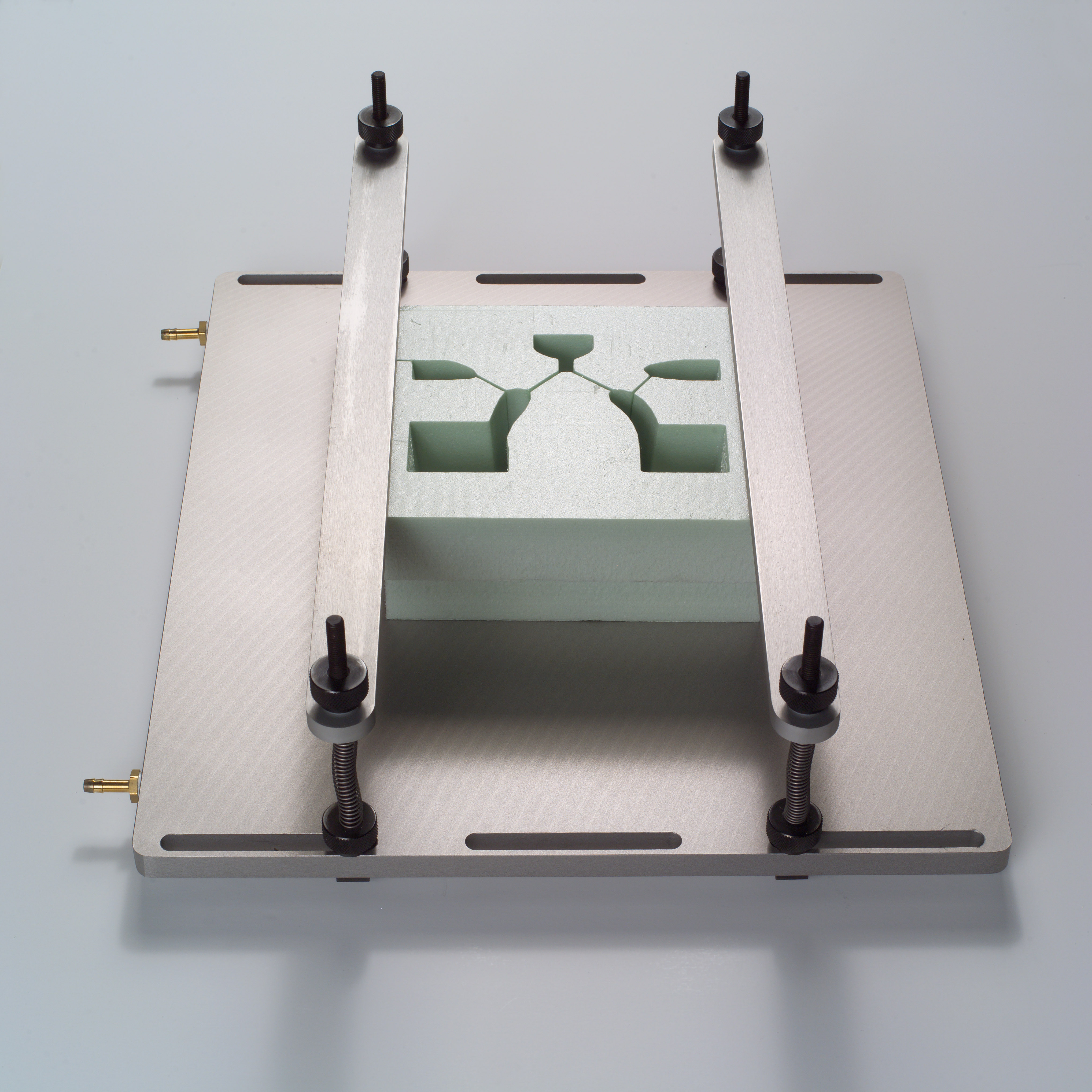

Pouring Plate with Cooling Unit Pouring / cooling plate for quickly cooling down the block alloy. The combination of cooling plate and cooling unit minimises cavitations and

provides block solidification in less than 20 minutes. The pouring / cooling plate has adjustable mounting bars so that it can be used with styrofoam blocks of different sizes. Pouring Plate Data

-

Aluminium for best heat dissipation

-

Prepared for open or closed water circuit with additional cooling unit

-

Effective area : 400 x 400 mm

-

Total area : 450 x 400 mm

-

Max. foam thickness : 100 mm

-

Weight approx. 11kg

Cooling Unit Data

|

|

|